Ranbao Controller: Efficient and Transparent Production Matching Precise Quality Traceability

Case Description

Shanghai Ranbao Controller Co., Ltd. is a Sino foreign joint venture specializing in electronic control devices for gas appliances. It faces challenges such as opaque inventory management, difficulty in real-time monitoring of production progress, and complex quality traceability processes. At present, ERP and manufacturing operation management platform have been implemented, building an intelligent and interconnected new ecosystem covering group decision-making to unit control. By optimizing warehousing operations through a barcode management system, accurate correspondence between material inbound and outbound orders has been achieved; Multi system integration and unified master data management enhance data analysis capabilities; The application of industrial PDA devices has improved the efficiency of scanning operations.

Application Products

ERP MOM

Company Profile

Shanghai Ranbao Controller Co., Ltd. was established in June 2000 as a Sino foreign joint venture jointly invested by Linne and Japan's RB Electronic Controller Co., Ltd. The company mainly produces electronic control devices and ignition devices for various gas appliances. It has 150 employees, covers an area of nearly 7000 square meters, and has an annual sales volume of nearly 300 million yuan. Its products are exported to Brazil, Japan, the Philippines, South Korea, Taiwan, China, China and other parts of the world.

Project background

The production status is opaque: it is difficult to grasp the production progress, inventory of work in progress and finished materials in real time, verbal communication takes a long time, the workload of statistics is large, and it is greatly affected by inventory, manpower, and equipment factors.

Difficulty in quality process control: The quality traceability process is complex, with long cycles, low efficiency, and even the problem of interrupted leads. It is necessary to quickly identify information such as raw material suppliers, operating equipment, personnel, processes, time dates, and process parameters.

Formula safety: Ensure formula safety without affecting production and procurement processes.

Solution

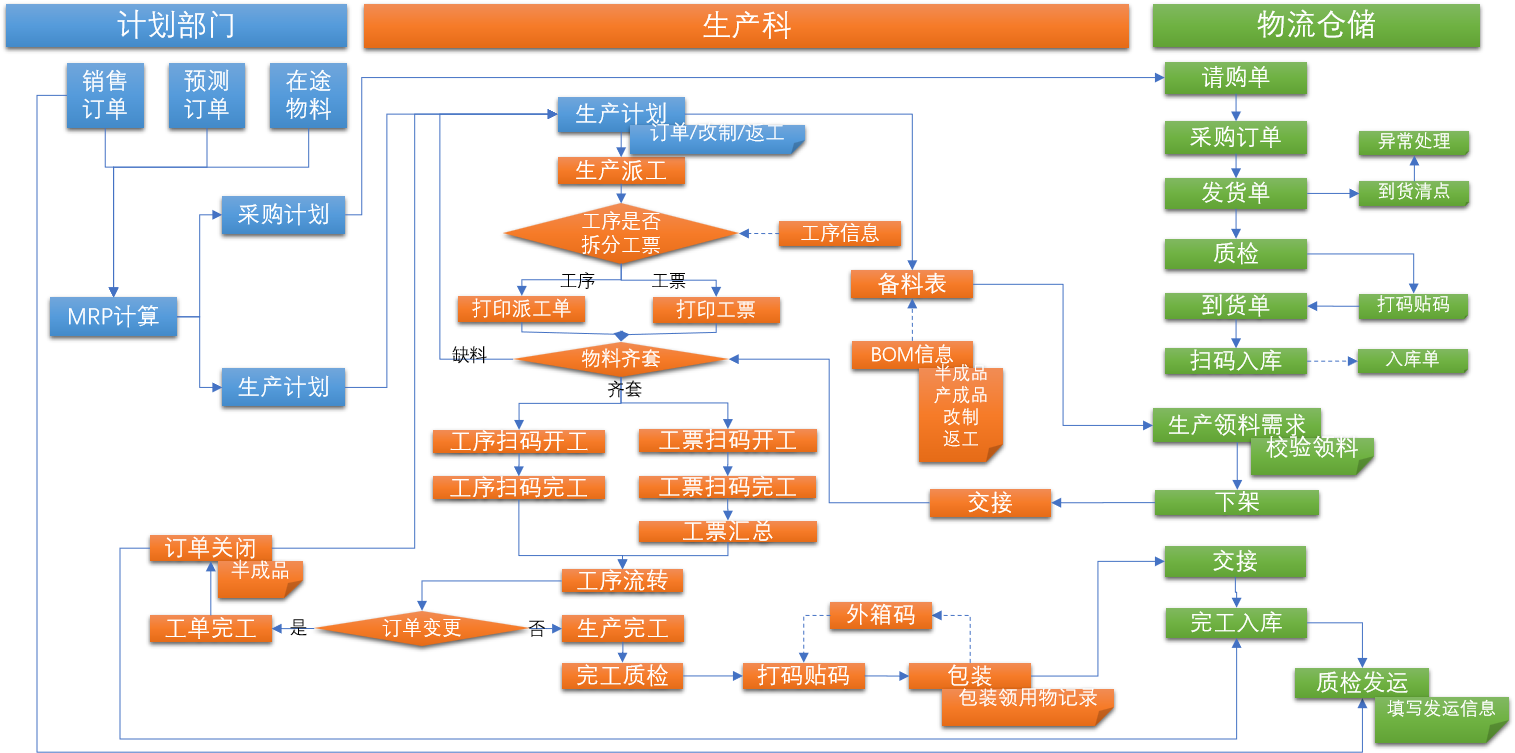

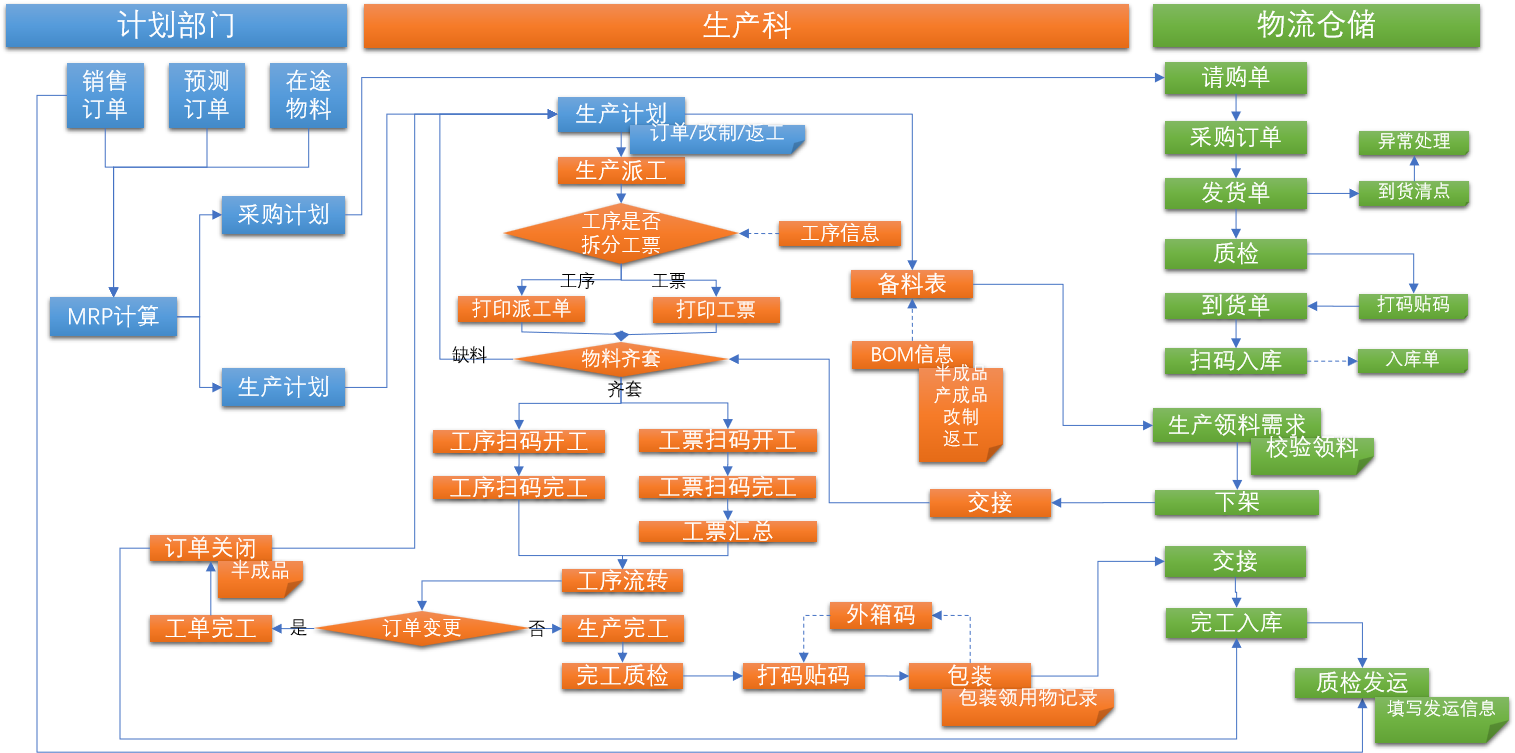

Informationization+Intelligent Factory Architecture: Through hierarchical linkage, comprehensive coverage from group level decision analysis to unit control is achieved, including the integration of ERP, MES+WMS (Process Collaborative Management System), PCS (Process Control System) and other systems, ensuring real-time monitoring and analysis of production operations, as well as active collection and early warning feedback of on-site execution.

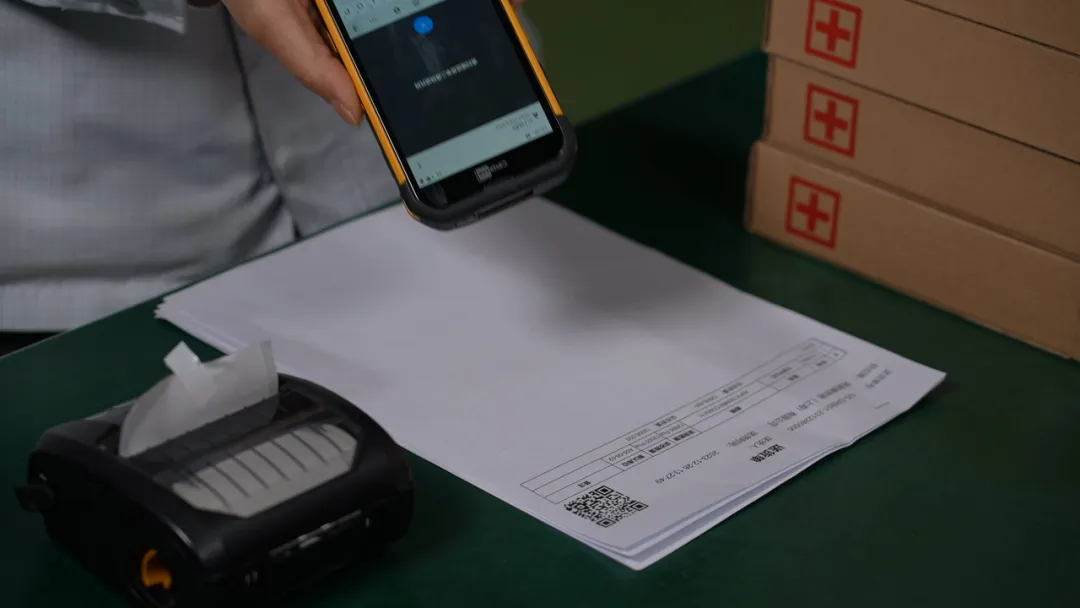

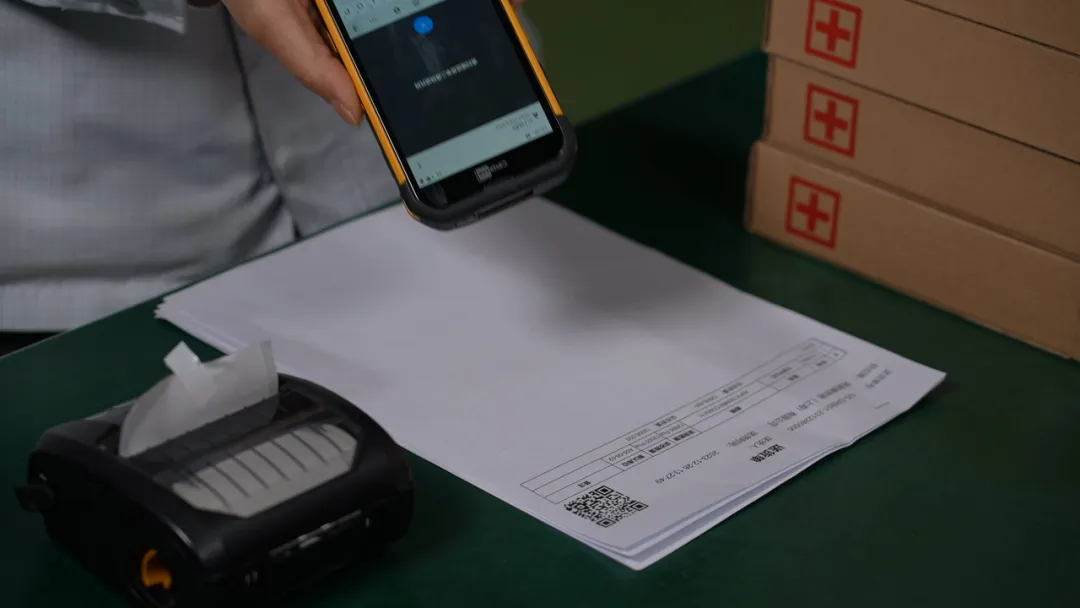

Basic construction of workshop warehousing: Caijiang Intelligent introduces a barcode management system to attach QR codes to each storage location and material to establish a digital label file. Through PDA, the complete digital material history of the entire process from unpacking and warehousing of raw materials to picking and transferring production is recorded in real time. We have achieved accurate correspondence between material inventory and orders, synchronized inventory records, and accurate cross departmental handover.

Workshop visualization: The Talent Craftsman MOM system will automatically generate dispatch orders and transfer orders. After workers use PDAs to scan the part codes and put them on the shelves, the system will automatically match and verify whether the part models, quantities, and batches are correct; And automatically calculate the transfer quantity based on the demand and inventory of the dispatch order, helping production personnel save time on manual verification and calculation, greatly improving the efficiency of parts transfer, and achieving synchronization between physical objects and the system.

After production is completed, workers only need to fill in production process information such as quality and working hours in PDA, and the system will automatically deduct raw material related data for finished product calculation and analysis, and finally carry out finished product warehousing. In addition to optimizing business processes, large screens have also been set up in workshops and warehouses for real-time data display. In this way, the entire conversion process from parts to products can be monitored in real-time in the system, achieving visualization of the production workshop.

Quality management of "production process": In order to improve the stability of product quality, we have adopted the most critical and complex Japanese Fuji brand high-speed surface mount machine and AOI automatic optical inspection equipment in SMT production to achieve high-speed and high-precision placement of components and automatic identification of various defective states of parts.

Through the barcode scanning system, we can ensure that the correct patch parts are placed in the accurate position on the PCB substrate. Any one of the photo combinations is incorrect, and the PDA will sound an alarm. In addition, through automatic optical inspection equipment (AOI), the image of the tested substrate is compared with the image of the sample substrate, which efficiently meets the requirements of substrate miniaturization and high integration. The combination of digital systems and automation equipment has helped us truly achieve process quality management, ensuring that non-conforming products are not manufactured or released.

Multi system integration: Unified master data management enhances data analysis capabilities, reduces manual statistical workload, improves the speed of providing basic data for cost accounting, and improves financial accounting processing efficiency.

Hardware support: It is recommended to use industrial PDA devices that are suitable for different scene requirements, such as Xinji RK95, RS31, RK25, etc., to ensure the efficiency and accuracy of scanning operations.

Application value

Improved production efficiency: One item, one code picking efficiency has increased by 70%, and the one click in/out function has saved a lot of labor costs.

Strengthening quality management: The application of digital systems combined with automation equipment has standardized the process quality management system, ensuring that non-conforming products will not be manufactured or leaked.

Enhance data utilization: Big data collection, cleaning, and capture technology has changed the traditional model of relying on experience management, and instead adopts precise digital analysis management to achieve in-process and real-time management.

Improved production line behavior: Promoted standardization of production operation management, improved product quality, and reduced defect rates.

Optimize resource allocation: reduces work in progress (WIP), improves resource capacity utilization, shortens abnormal downtime, and enables better evaluation of personnel and equipment performance.