Kaishitong Semiconductor: Accurate Cost Accounting and Efficient Collaboration among Multiple Organizations

Case Description

Kaishitong is facing problems such as inaccurate cost accounting, lack of scientific demand planning, and cross organizational data silos. Through the introduction of intelligent industrial Internet solutions, it has realized the unified management and refined cost accounting of sales, procurement, outsourcing and production businesses. At the same time, it has established a structured general ledger management system to solve the problems of information sharing and business collaboration within the enterprise.

Application Products

ERP CJ- ABC MES

Company Profile

Shanghai Kaishitong Semiconductor Co., Ltd. (hereinafter referred to as "Kaishitong"), as an enterprise engaged in the research, production, and sales of high-end ion implantation machines, has a wide range of applications in the fields of photovoltaic solar cells, new flat panel displays, and semiconductor integrated circuits. Listed on the New Third Board in 2016 and merged into Wanye Enterprise in 2018.

Project background

Inadequate cost accounting: unable to automatically obtain and allocate various expenses to specific products, resulting in inaccurate cost calculation.

Formula safety issue: It is necessary to ensure that the formula is safe and does not affect the production and procurement processes.

Unscientific demand planning: imbalanced order supply and demand, inaccurate calculation of material list.

Cross organizational data silos: Lack of effective information sharing and collaboration mechanisms between different factories.

Solution

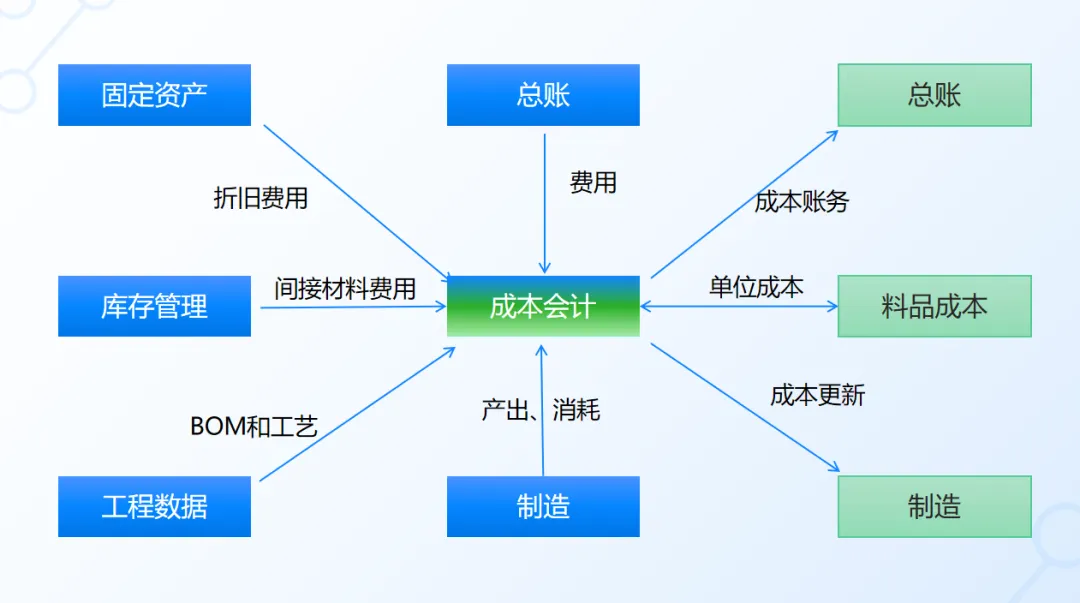

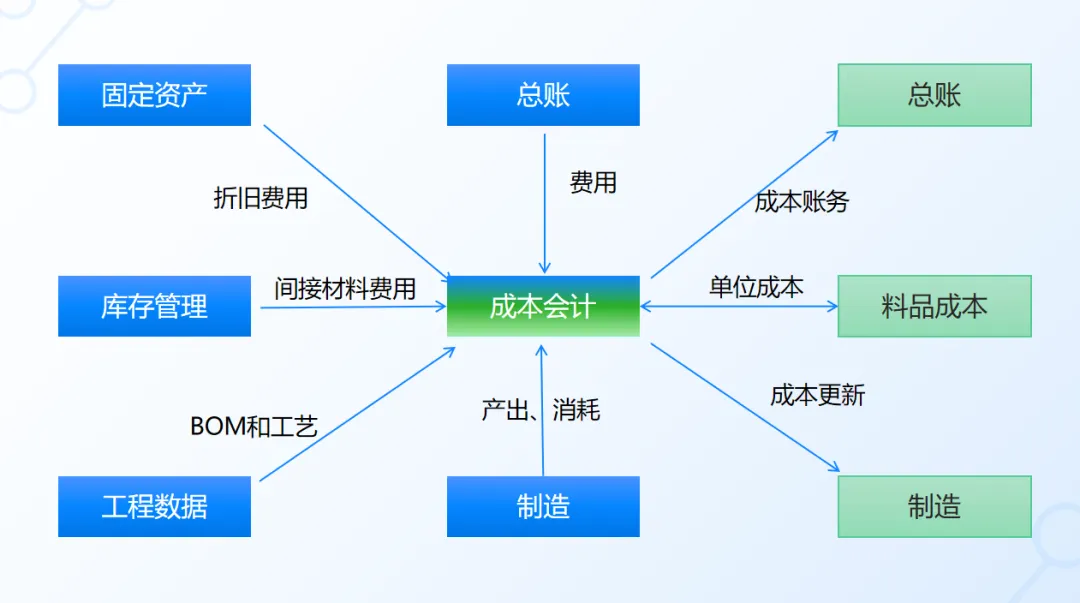

Financial field: Implement accounts receivable management, accounts payable management, and general ledger management, establish a standard financial management process with accounting tables as nodes, and ensure the linkage between cost calculation and general ledger modules.

Supply chain field: covering sales management, procurement management, inventory management, and material demand planning, optimizing the demand planning process to ensure accurate matching of order supply and demand relationships.

Manufacturing field: supports full process production management from forecast orders to completion and warehousing, utilizing MRP (Material Requirements Planning) and MPS (Master Production Planning) for capacity load analysis to improve production efficiency.

Cost domain: Provide material cost management, optimize the cost calculation process, and achieve visualization of cost calculation results.

Characteristic area: Implement a multi organizational management model, centrally control price lists, facilitate efficient collaboration among various organizations within the group, and reduce business costs.

System integration: Integrate with the NC system to meet the integrated management needs of our unit's business and finance, and reduce manual duplication of input work.

Mobile application: Complete warehouse material entry and exit management through mobile scanning, interact with ERP system in real-time, and improve warehouse management efficiency.

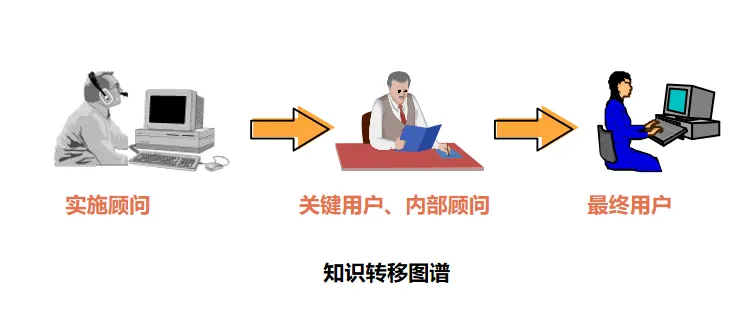

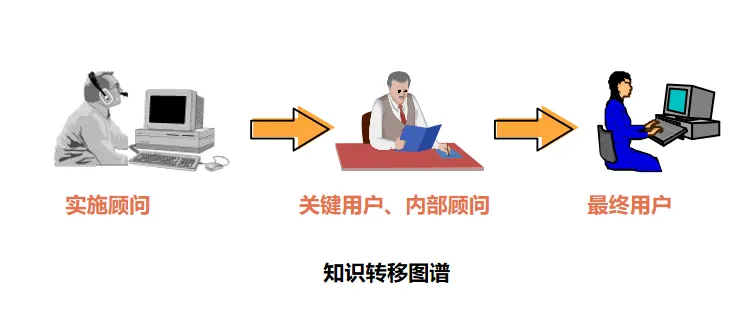

Training and Support: Provide comprehensive training on key user operations, help enterprises establish a knowledge transfer system from implementation consultants to internal consultants to end-users, ensure that users can proficiently master the system usage methods, and promote knowledge transfer.

Application value

Implemented business process streamlining, improved various data tracking and traceability capabilities, and achieved real-time monitoring of business situations. In addition, it has improved the precision and accuracy of cost accounting, strengthened business collaboration among multiple organizations, and ultimately achieved the goal of cost reduction and efficiency improvement. Especially, upgrading from manual operation to convenient operation on both PC and mobile devices has increased overall work efficiency by 70% and shortened sales cycles by 25%.